About Us

MANAGEMENT

Enginuity Power Systems’ committed team consists of former deep-tech, energy efficiency solutions, power products, co-generation products, scalable software, and consumer electronics executives who throughout their careers have been business owners, entrepreneurs and innovators.

Tony Uttley

CEO / Board MemberExecutive Team

Britt Eichten

CFO and EVP Shared Services

Levi Bouwman

Chief Revenue Officer

Nate Kraft

Chief Product Officer

Kelly Rosenberger

EVP / Government BusinessSenior Leaders

Michael Alfano

SVP / Sales Support

Dan Balogh

SVP/Product Development and Engineering

Sanjay Gospodinov

Head of Strategy and Chief of Staff

Vince Meyers

SVP / Customer Success

John Morris

SVP / Commercial and Supply Chain

Phil Zoldak

VP Government Engineering and R&DBoard Members

Pete Kirsch

Board Chair / Board

Datta Godbole

Board

Greg Powell

Founder / BoardPublished Papers

Enginuity

Achievement

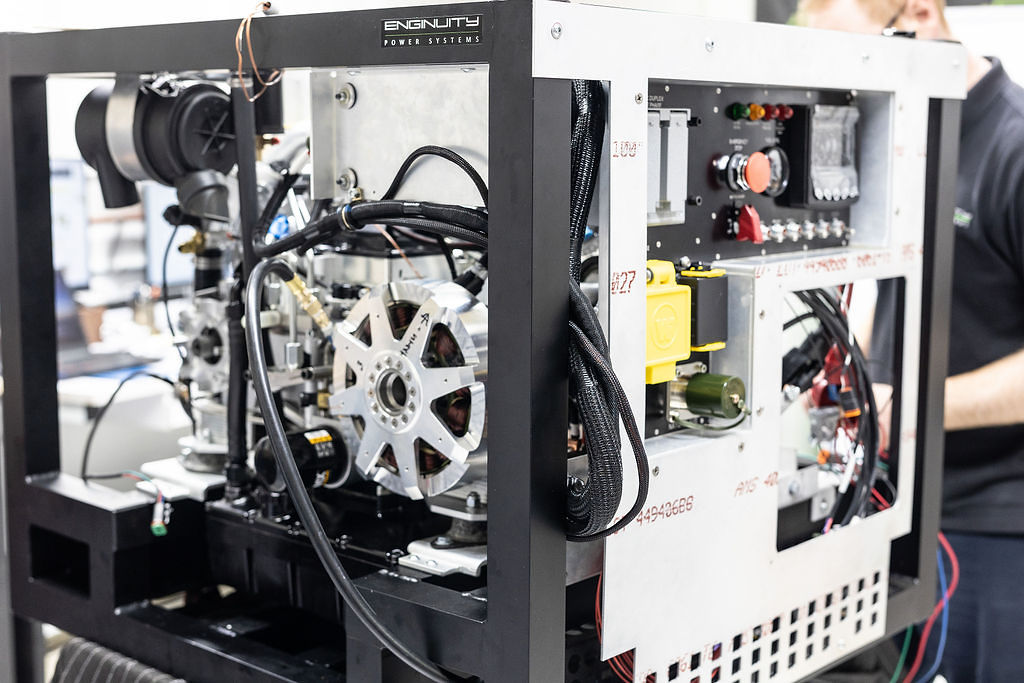

Enginuity Power Systems has created the next generation of engine and generator technology with its patented, four-stroke, inwardly opposed piston engine.

Our engines are dynamically scalable, quiet, 25-30% more fuel and thermally efficient than conventional technology, light weight, and multi-fuel capable.

‘Simply Efficient,’ our goal, is to provide power and energy systems that are clean, highly efficient and provides the consumer with long-term sustainable, resilient, and reliable power system at an affordable price. In today’s world of uncertainty, Enginuity provides homeowners, businesses, and installations with assured power and energy capability; even in the wake of disasters.

Our

Technology

Enginuity is producing the next generation of advanced appliances, hybrid generators, advanced military applications – all driven by Enginuity’s advanced modular technology that offers scalability and lightweight performance – previously unavailable on the market.

Enginuity

History

Since its inception, Enginuity Power Systems has focused on developing and providing highly reliable and energy efficient power systems, based on patented technology. Enginuity has worked with the U.S. Army for over 5 years to prototype a next generation ruggedized tactical hybrid generator. That ongoing development program has highlighted Enginuity’s expertise within the power space and allows the company to serve as a trusted partner for our customers.

Enginuity has also developed foundational patents to help provide innovative, state-of-the-art combined heat and power systems to the light industrial, commercial, residential and defense markets. These products provide on-site electricity as well as heating and cooling “behind the meter” in applications like hospitals, schools, agriculture, multi-family housing and commercial real estate. The Company’s products are a critical solution to today’s impending energy crisis.

Enginuity

Management Team

Enginuity’s management team is made up of experts and experienced operators across deep-tech, energy efficiency solutions, power products, co-generation products, scalable software, and consumer electronics. The team has experience building and growing companies, launching hundreds of engineered products, building two-step distribution channels, and making new markets.

The management team’s experience comes from organizations such as U.S. Army, NASA, BCG, Quantinuum, Honeywell, Resideo, Digital River, Techtronic Industries, Yanmar, Tedom, Antylia Scientific, Brunswick Corporation, Belkin, and Sony.

Enginuity

Upcoming

Through programs funded through the Department of Defense, Enginuity will be supporting the continued refinement and product release of its integrated, hybrid tactical generator for the U.S. military as well as the creation of a resilient and energy-efficient micro-grid for the National Guard.

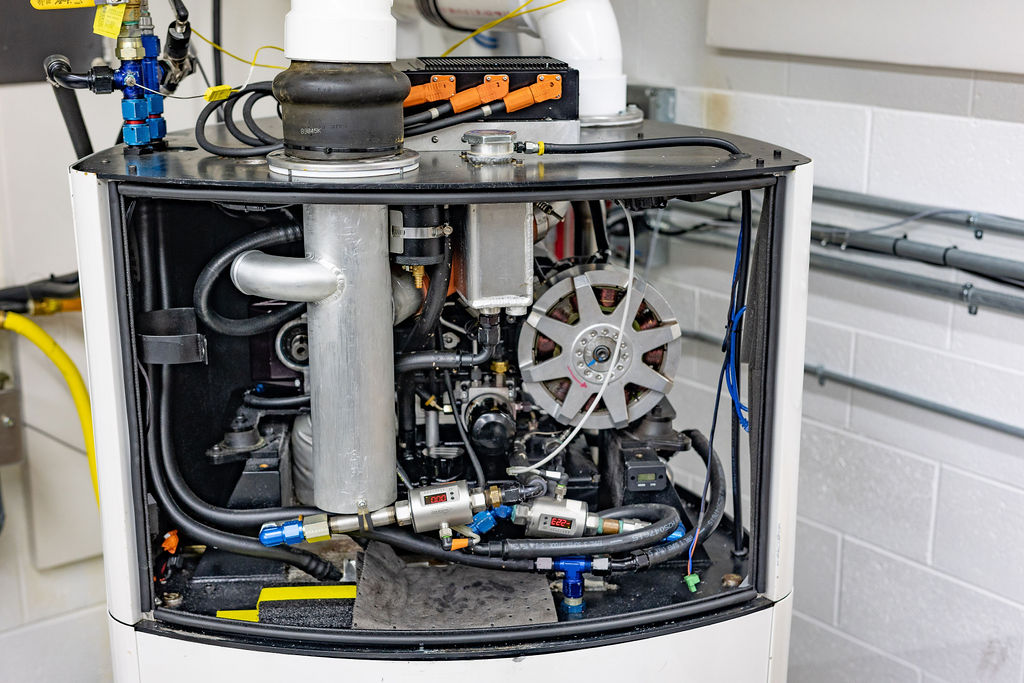

Enginuity is also in the process of launching its inaugural combined heat & power (CHP) product, the E|200. In partnership with global integrated energy group, Kiturami, Enginuity will be releasing a family of high quality, resilient CHP products while working with distribution partners throughout North and South America to install and maintain the energy products.

History

Since its inception, Enginuity Power Systems has focused on developing and providing highly reliable and energy efficient power systems, based on patented technology. Enginuity has worked with the U.S. Army for over 5 years to prototype a next generation ruggedized tactical hybrid generator. That ongoing development program has highlighted Enginuity’s expertise within the power space and allows the company to serve as a trusted partner for our customers.

Enginuity has also developed foundational patents to help provide innovative, state-of-the-art combined heat and power systems to the light industrial, commercial, residential and defense markets. These products provide on-site electricity as well as heating and cooling “behind the meter” in applications like hospitals, schools, agriculture, multi-family housing and commercial real estate. The Company’s products are a critical solution to today’s impending energy crisis.

Management Team

The initial management & founding team includes former business owners, entrepreneurs and innovators with deep engine technology and supply chain expertise.

In 2019, Enginuity hired a former DOE official and cleantech executive to strengthen its business development capabilities, a senior DoD employee and contractor to lead our DoD penetration efforts, and a senior manufacturing expert to help transition to an expanded production scale.

Upcoming

We are aiming to generate initial revenues through government contracts and private sector pilot programs. We are pursuing multiple Department of Defense (DoD) and Department of Energy (DoE) programs and participating in the Army Expeditionary Warrior Experiments.

We attend trade shows (International Builders’ Show, AHR Expo, Power Up Energy Expo, National Summit on Combined Heat and Power, CMPX, POWERGEN International) to demonstrate our private generation. We are also seeking additional external validation through national labs and utility testing and demonstrations.

We encourage everyone who believes they can contribute their talents and expertise to the growth of Enginuity, to submit their resume or a short bio to us here at [email protected] even if a specific job posting isn’t active below.

The Company is not expected to sponsor employment visa applications at this time.

PRINCIPALS ONLY. We are an equal opportunity employer.

Active Job Opportunities include:

Enginuity

Careers

Enginuity is growing fast and we are constantly looking for talented individuals to join our team. We are anticipating growth in the areas of accounting and finance, business development, mechanical and electrical engineering, software development and government proposal writing. Experience with areas of Appliances, Standby Generation, Utilities, Distributed Energy, Software & Controls, Building Technologies & Automotive OEM industries is a plus, however, not required.

Enginuity

Today

Enginuity Power Systems is introducing the next generation of ultra high-efficiency engines, to manufacturers and consumers, for applications in: broad home & light industrial appliance, portable power generation and transportation.

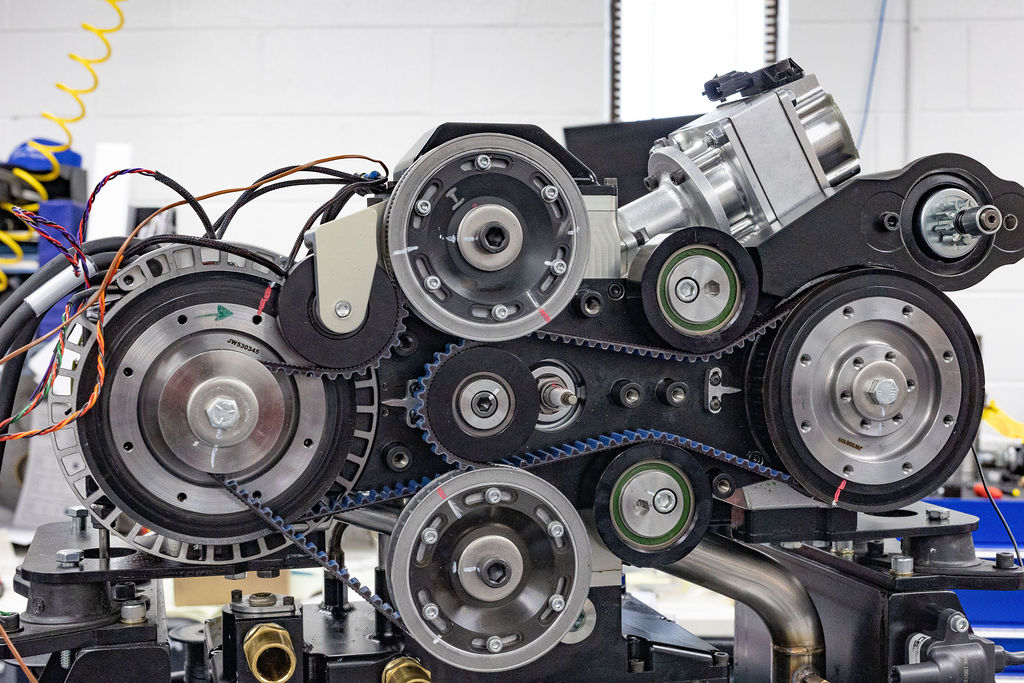

The Enginuity platform is built on the technological foundation provided by the world’s first production-ready four-stroke, inwardly-opposed piston engine. Enginuity’s simplified engine design has a number of operational advantages that current engines just can’t match.

Rigorous testing at an independent lab has provided validation that the Enginuity family of small generator engines outperforms commercially available generator engines by demonstrating 27% higher fuel-efficiency and reduced emissions.

Enginuity

Breakthroughs

Enginuity’s engine does not have a cylinder head, which cuts the number of moving parts in half. This avoided complexity enables the engine to reach efficiency numbers that far exceed those of conventional engines. Other innovations such as our ‘adiabatic-interface’ and our patented ‘mirror-balanced’ low-vibration design compound these performance benefits.

Who Implements

An Enginuity Engine?

If you are an original equipment manufacturer or government contractor searching for a clean, quiet, efficient, virtually vibration-free generator engine for virtually any application, there is no commercially available power-production system that has the performance/cost value of deliverable benefits than we have in the Enginuity Power Systems portfolio of intellectual property.

Enginuity can provide you with a substantially more efficient engine custom tailored for your specific needs

For every type of power generation need, for whatever type of system you are building, Enginuity can provide you with a substantially more efficient engine, custom tailored, for your specific needs. Our proven performance, reduced parts content, and simple design makes us an ideal commercial development partner.

Enginuity is also working on military spec multi-fuel micro-generator...

Enginuity is also working on a military spec, multi-fuel, micro-generator to replace 90 lbs. of batteries with an engine that weighs less than 30 lbs; while generating up to 2 kilowatts of power. This lightweight portable generator will allow military teams in the field to move faster, stay connected to their support, and have a consistently full charge for electronic assets.

There are also a variety of transportation applications, requiring very few architectural changes, that are in development. These concepts include Electric Vehicle (EV) range extenders, hybrid applications for commercial and off-road usage and public transportation fleets.

What’s

Next

Due to the power production our engine designs make possible, we are excited to introduce the first ‘new’ at-home appliance since the microwave oven: a multi-fuel, private home generation appliance. You can think of our system as a water heater that also has the ability to provide most, or all, of the electricity and heating needs for your home or business; virtually eliminating your electricity bill.

Enginuity Power Systems

Products

Private Home Generation Appliance (Enginuity 8kW System)

It’s a Conventional Water Heater (That Just Happens To Make All Your Power, Too!)

Larger Residential Homes and Light Commercial Applications

RIHGS is a Load Following Power System Designed to Extend Operational Mission Time, Reduce Fuel Consumption, and Ensure Operational Flexibility in a Multi-Domain Operating Space